Chemical resistance of textiles designed for Personal Protective Equipment can be evaluated through different standard test methods. The choice of these test methods depends on the protective level and the final application, directly related to the specifications.

Visual penetration: ASTM F903 Resistance of Materials Used in Protective Clothing to Penetration by Liquids. This method is intended to evaluate visually the liquid penetration of any chemical that can be handled by the laboratory. A reservoir cell has one wall made of the tested laminated or coated fabric. The chemical is filled into the cell. The standard sequence applies various pressure on the chemical to challenge the textile barrier.

Visual assessment is performed to detect the penetration. This method is also adapted to perform penetration by synthetic blood, under the standard test method ASTM F1670 designed for textile barriers used in hospital and surgical rooms.

Weight difference and repellency: ISO 6530 Protective clothing – Protection against liquid chemicals – Test method for resistance of materials to penetration by liquids.

Also known as the gutter test, this method evaluates the liquid repellency and absorption. The barrier fabric is placed on a gutter with an inclination of 45°. The challenge chemical is dropped on top of the gutter and the liquid falls down the gutter, over the fabric. Weight differences are measured at different stages: collected chemical indicated the capacity for repellency, fabric weight indicates the absorption level while a blotting paper underneath the fabric indicates a level of penetration.

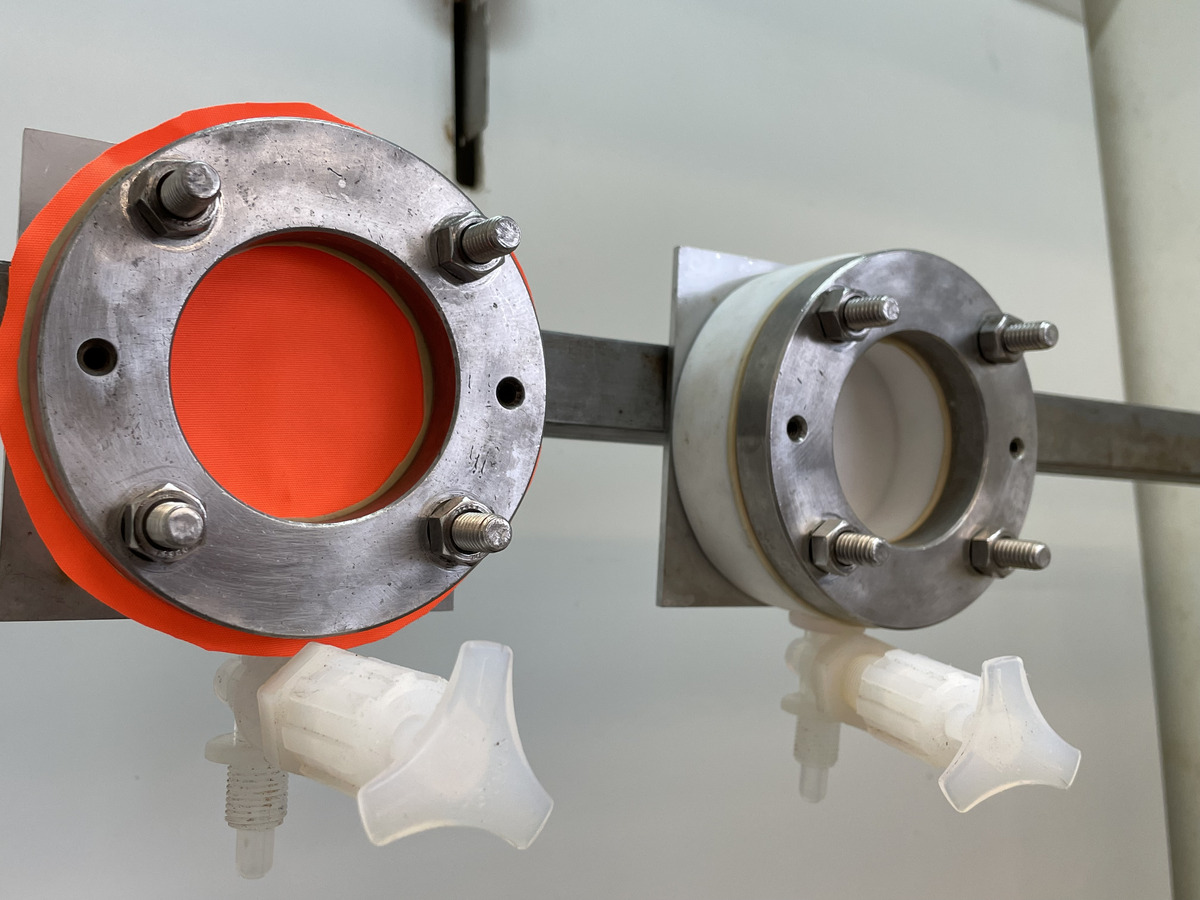

Chemical detection: ISO 6529 and ASTM F739 Permeation of Liquids and Gases Through Protective Clothing Materials Under Conditions of Continuous Contact is a more technical test method. A test cell encloses the fabric with one side in contact with the liquid or gas chemical, the other side of the textile is also in a closed chamber where a carrier gas is collected and sent to a sensor. The molecules of the challenge chemical are detected and measured for a concentration level.

The breakthrough time is fixed at 1.0 µg/cm²/min for ISO 6529 and 0.1 µg/cm²/min for ASTM F739.

Detection technique and detection limit are defined by the user, as well as the challenge chemical

Depending on the application, these test methods are applied with specifications related to personal protective equipment such as NFPA 1970 combining Protective Ensembles for Structural and Proximity Firefighting, Work Apparel and Open-Circuit Self-Contained Breathing Apparatus (SCBA) for Emergency Services, and Personal Alert Safety Systems (PASS) (originally NFPA 1971 ; NFPA 1975, NFPA 1981 and NFPA 1982), NFPA 1990 for CBRN protection (that includes NFPA 1991 ; NFPA 1992 and NFPA 1994), AAMI PB70 for surgical drapes and gowns, or other first responders specification.

Common chemicals are used for such tests, depending on the specification and application needs:

- Synthetic blood,

- Aqueous film-forming foam (AFFF),

- battery acid,

- Fire-resistant hydraulic fluid,

- phosphate ester base,

- Surrogate gasoline,

- Swimming pool chlorinating chemical containing at least 65 %-free chlorine,

- Automobile antifreeze fluid,

- NaOH,

- HCl,

- H2SO4,

- o-Xylene,

- Isopropanol,

- Butyl-Acetate,

- Dimethylformamide,

- etc…

CTT, at the heart of the matter.

info@gcttg.com

ASTM F739