Flammability | Technical Services

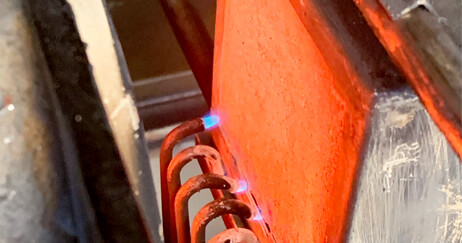

In general, flammability tests are used to determine the ignition capacity of a textile material in the presence of pure flame, radiant heat, or a combination of both. They concern all textile products, but particularly personal protective equipment, textile materials and products used in the transportation sector.

BEHAVIOUR OF MATERIALS

Flammability

Our capabilities for assessing the flammability behaviour of materials include several types of measurements:

(PPE)

PERSONAL PROTECTIVE EQUIPMENT

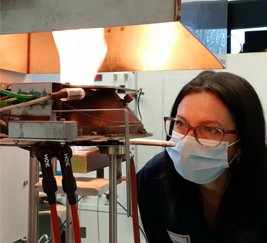

CTT Group has developed a particular expertise in flammability testing adapted for PPE.

Beyond the flammability of the material itself, our tests can determine the thermal protection factor of a garment, which is the amount of heat and the rate at which it passes through a material. This data is of vital importance when it comes to, for example, firefighter clothing (NFPA 1971).

The development of textiles for certain PPE also requires this type of characterization, notably for welders (EN 11611), electricians (NFPA 70E, ASTM F1506) or workers in contact with hydrocarbons (NFPA 2112).

STRICT FLAMMABILITY STANDARDS

TRANSPORT

Flammability testing also applies to many materials used in the transportation industry, from seat belts to the interior trim of an airplane or subway car. All of these components must meet strict flammability standards.

The tests conducted by CTT Group’s flammability laboratory will, for example, measure the density of smoke released by a burning material (ASTM E662). Again, this is life-saving data since smoke that is too opaque could prevent passengers in a burning subway from finding the emergency exits.

The CTT Group team can also help organizations improve the heat capacity of their products through the use of a calorimetric cone (ASTM E1354) or radiant panel indices (ASTM E162 or ASTM E648 for floor coverings). We can also determine the toxicity of fumes generated by burning materials.

Standard method for flame tests of flame resistant fabrics and films

CAN/ULC S109-14-R2019

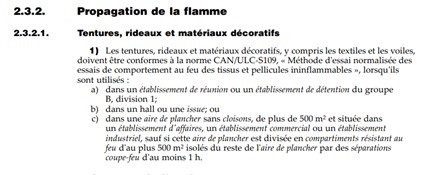

The CAN/ULC S109 method is a flammability test for non-flammable textiles and plastic films used in the manufacture of draperies, awnings and curtains. The test evaluates the behavior of these products when subjected to low intensity fire.

The method is divided into two tests:

- 1The small flame test consists of placing the tested specimen in a vertical position and applying a flame of 40mm height for 12 seconds on its lower end.

- 2The large flame test consists of placing the tested specimen in a vertical position and applying a flame of 280mm height for 120 seconds on its lower end.

If the tested samples are intended to be washed and/or dry-cleaned during use, the small flame and large flame tests must be carried out after washing and/or dry cleaning

If the tested samples will be subjected to outdoor conditions during their final use, the small flame and large flame tests must be carried out after soaking, rubbing and accelerated aging.

To satisfy the method requirement, the tested sample must not have any debris or residue that buckles for more than 2 seconds after separation and must have an average damaged length of less than 165mm with no specimen having a damaged length of more than 190mm.

In Canada, the CAN/ULC S109 method is one of the requirements of the Code National de Prévention des Incendies (CNPI) or National Fire Code of Canada drawn up by the NRC.

The CNPI is the “model” national text, revised every 5 years by a committee of experts (architects, engineers, firefighters, prevention specialists, etc.).

The provinces are responsible for establishing a text of their own with the possibility of adopting the CNPI. Provincial laws may include an identical or modified version of the CNPI, but the latter can only be more severe than the model text.

Extract from the National Fire Code

Canada 2020

The CNPI is the “model” national text, revised every 5 years by a committee of experts (architects, engineers, firefighters, prevention specialists, etc.).

The provinces are responsible for establishing a text of their own with the possibility of adopting the CNPI. Provincial laws may include an identical or modified version of the CNPI, but the latter can only be more severe than the model text.

Currently, all provinces adopt an identical or modified version of the CNPI, which makes the CAN/ULC S109 method a requirement for the evaluation of the fire resistance of curtains, draperies and other decorative materials.

OTHER TEXTILE PRODUCTS

All clothing, especially children’s sleepwear, as well as textile materials for furnishings (mattresses, furniture covers, rugs, carpets, etc.), tents and outdoor canvas shelters, must meet flammability standards under the Canadian Textile Flammability Regulations.

Special requirements, such as CAN/ULC-S109 or NFPA 701, apply to textiles for tents or shelters, and for tensioned or decorative building fabrics. CTT Group can help you develop your products in accordance with these requirements.

We have the expertise and equipment required to perform standardized flammability tests specific to each product. Therefore, we can assist you in your development efforts to ensure that your products comply with standards.

Special tests can also be designed for your specific needs.