Materials engineering needs precise evaluation and thermal analysis services is part of them. The following technics: Dynamic Mechanical Analysis (DMA), Thermomechanical Analysis (TMA), and Dilatometry are used for polymers testing as well as composite materials.

Dynamic Mechanical Analysis (DMA)

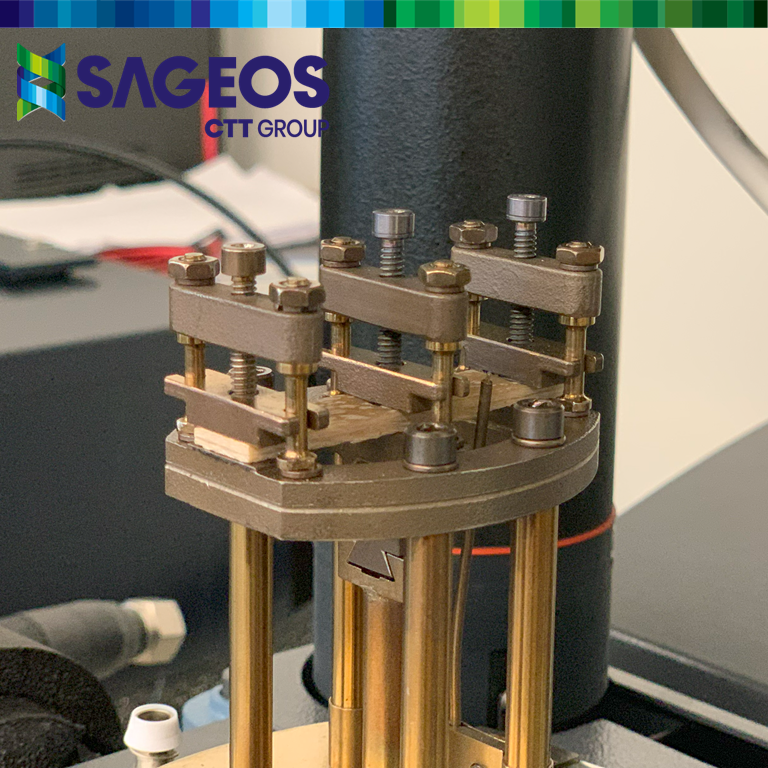

DMA is a technique in which the elastic and viscous response of a sample under oscillating load, are monitored against temperature, time or frequency. Our DMA machine offers all the major deformation modes such as bending (single cantilever, dual cantilever, and 3-point bend), shear, compression, and tension required to characterize polymers, elastomers, foams, composites, thin films and fibers. DMA provides the oscillatory or static force over a wide range (0.0001 to 18N) operating at frequencies between about 0.01 and 200 Hz enabling a broad spectrum of material properties to be measured. The cooling system using cold nitrogen gas extends the operating range to sub-ambient temperatures while our DMA machine can reach up to 600˚C. Dynamic mechanical testing – according to standards such as ASTM D4065, D5023, D5024, D5026, D5279, D5418, D7028, and ISO 6721 supports product development for:

- Determination of glass transition temperature (Tg)

- Analysis of viscoelastic behavior

- Assessment of curing processes and crosslink density

- Evaluation of fiber-matrix interactions

- Determination of storage, loss, and complex modulus

- Measurement of dynamic modulus and damping properties (Tan Delta (δ))

- Analysis of temperature-dependent behavior

- Study of vulcanization and aging processes

Thermomechanical Analysis (TMA)

TMA measures material dimensional changes under controlled conditions of force, atmosphere, time, and temperature. TMA measures intrinsic material properties (e.g., expansion coefficient, glass transition, Young’s modulus), plus processing/product performance parameters (e.g., softening points). Our equipment features a non-contact, friction-free motor delivers forces from 0.001 N to 2 N enabling measurements on the widest range of samples from soft compressible elastomers to stiff composite materials. Its mechanical cooling accessory provides controlled cooling to -70 °C. According to standard methods (e.g. ASTM E831 and E1824) TMA is critical to determine:

- Suitability of materials for use in harsh environments and at extreme temperature

- Glass transition temperature (Tg) of polymers

- Coefficient of thermal expansion

- Dimensional stability of parts at operating temperature and loading

- Shrinkage of oriented films

- Softening temperature of amorphous and semicrystalline materials

- Compatibility of materials that must function together like coatings/substrates, adjacent layers of laminates, seals.

Dilatometry

The principle of dilatometry methods is to measure the materials volume variation as a function of the change in temperature. Dilatometry can be used to test a wide range of material including traditional and advanced ceramics, glasses, metals, and polymers. During the experiment, the linear dimensional change (expansion or contraction) of the sample is measured by a highly accurate displacement sensing system. There are different methods adapted to be used for dilatometry like ASTM D696 that covers determination of the coefficient of linear thermal expansion for plastic materials. This analysis allows optimization of workpiece shapes and processing temperatures, improvement of product quality and reduction of costs. Our DIL 802 as a classic horizontal push rod dilatometer, measures the thermal expansion of a specimen (0-50mm) placed horizontally in a furnace by scanning its head end with a push rod. The DIL 802 is designed for measurements under vacuum or inert gas.

CTT Group, at the heart of the matter