Created in 2021, the EcoTextile Research Chair engages in a range of research and development activities that support the textile, textile-based flexible materials, geosynthetics and advanced materials industries in their transition to more sustainable processes.

Commitments by civil societies and individuals to the sustainable development goals set by the UN may seem complex and difficult to integrate into a product development or production technology process.

At CTT Group, we’re convinced that the future of textile manufacturing is green.

That’s why we’ve established the EcoTextile Research Chair, whose mission is to support the development of less energy-consuming, less polluting and more sustainable processes.

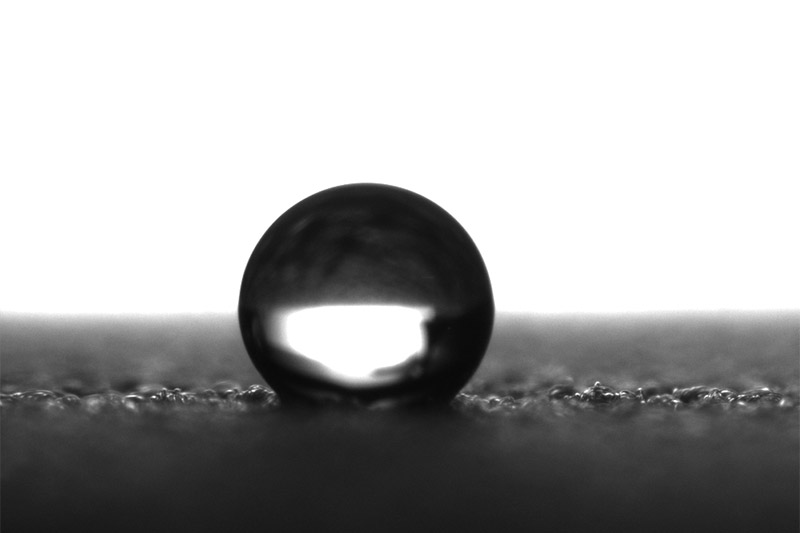

Performance validation by contact angle measurement of an eco-friendly water repellent finish for textiles (CTT)

Development of a process to soften biosourced fibers (CTT)

Milkweed seed fibers

RESEARCH FOCUSES

The EcoTextile Research Chair is involved in every stage in the life cycle of a textile product, in four major research areas:

- Natural fibres

Natural fibres represent an environmentally friendly alternative to synthetic materials. As renewable resources, their responsible use can have a low environmental impact.A number of the CTT’s activities involve assessing the feasibility, through the creation of prototypes, of using natural fibres such as hemp and milkweed in textile manufacturing.

- Green chemistry

Like many other industrial sectors, the textile industry is a consumer of chemical products at a number of stages in the materials manufacturing process.Our approach is to propose alternatives to generally used and potentially environmentally harmful chemical products by:

– Using biosourced and/or biodegradable materials to reduce the need for traditional chemical products.

– Replacing chemical products on environmental agency watchlists with solutions that are better for the environment.

– Reducing reliance on organic solvents and guiding a transition to aqueous-based formulations. - Recycling and biodegradability of finished products

According to the U.S. Environmental Protection Agency (EPA), only 29% of the 17 million tons of municipal solid textile waste generated in 2018 was recycled (clothing, shoes, sheets, pillow cases, etc.). Textile recycling and biodegradability are therefore a growing concern.Going beyond efforts to facilitate recycling, this research area promotes the use of recycled and biodegradable polymers in textile product manufacturing.

True to our comprehensive approach, we’re also working to develop methods for evaluating the biodegradability of polymers and textiles based on the latest knowledge and innovations available.

We’re also participating in projects aimed at recycling high-value-added textile polymer materials derived from personal protective equipment.

Finally, we’re actively working on recycling carbon fibres derived from composite material panels to create recycled carbon threads.

- Reduced energy costs

Reducing energy costs is an integral part of the UN’s 17 Sustainable Development Goals. We’re doing our part in our daily activities, but we’ve also initiated internal projects aimed at developing technical expertise in the following fields:– Photopolymerization: reduced energy consumption, water- and solvent-free formulation, rapid manufacturing times

– Reduced drying time for conventional production finishing processes

– Supercritical CO2 technology: reduced energy consumption, water- and solvent-free formulation

EXTERNAL LINKS