With winter slowly but surely approaching, the insulation capabilities of textile materials become relevant once again, whether you are a winter outdoor enthusiast, an outdoor worker, or someone who enjoys forest walks.

But did you know that textile materials are evaluated using specific methods and dedicated equipment?

For clothing, a commonly used method involves placing a textile on a heated plate, also named sweating guarder hotplate, maintained at 35°C in a climatic chamber kept at 20°C/65% RH, with wind passing over the textile surface. The temperature difference between the heated plate and the climatic chamber is kept constant, and the electrical power to maintain the plate at temperature is recorded. This value is inversely proportional to the insulation capacity of the textile. The more insulating the textile is, the less energy is needed to heat the plate.

Based on this principle, several equipment and methods have been developed. Here are some examples:

ISO 11092 and ASTM F1868 Part A measure the thermal insulation capacity of flat textiles. Multiple layers of materials can be measured together or separately, such as an inner lining, thermal insulation, and outershell textile. An option for perspiration through the heated plate also exists to measure the resistance to sweat evaporation, directly impacting the insulation capacity of textiles. More specifically, measurement equipment can be updated with options dedicated to well-defined applications. For instance, ASTM F3340 is a method using a cooled plate to determine the insulation of camping mattresses, while ASTM D1518 uses another type of accessory for fleece insulation systems.

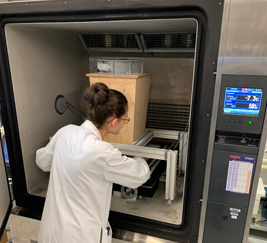

Regarding custom developments, CTT has developed the GCTTG 161 method, allowing insulation measurements with an ambient temperature down to -40°C and perpendicular wind to the textile up to 16 km/h. These developments are carried out as part of our work for the Nordic climate to simulate wind chill in winter conditions.

Flat measurement equipment has subsequently led to the development of 3D measurement devices for testing parts of the human body.

CTT has developed the CTT/PTC1, now GCTTG 168 method. This method, along with the equipment, was developed to meet the needs of Canadian shoe manufacturers for an objective measurement of the thermal comfort rating of winter boots. A right adult foot size 9 for men, size 10 for women, and a right child foot size 13 have been constructed to test boots accordingly.

Hands and heads also exist! Thus, these devices at CTT measure the thermal insulation of gloves, the right hand, as well as beanies with a thermal head, following methods such as EN 511 or ASTM F3426.

All these methods are available at the CTT for your developments: info@gcttg.com