How to create 3-dimensional fabric structures using a new embroidery technique called TFP (Tailored Fibre placement).

CTT Group is proud to announce the acquisition of a new cutting-edge equipment: a ZSK Technical Embroidery Machine. Among various capabilities, our newest equipment has a specific embroidery head designed for TFP process.

Figure 1 – ZSK Technical Embroidery Machine at CTT Group

TFP process aims to place a yarn of any nature, size or shape on a textile substrate according to a programmed pattern and holding it in place using a sewing yarn. It provides a great flexibility by allowing many various types of yarns to be processed through the TFP head : conductive yarns, fiberglass yarns and even carbon filaments.

The same versatility also applies to the design of the pattern, which can be quite dense or very open and can be made either in 2D or 3D.

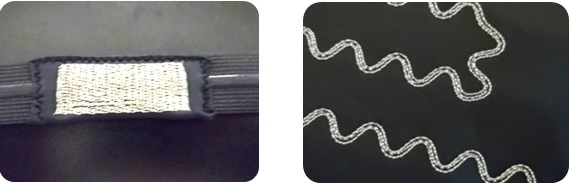

Figure 2 : Example of dense embroidered conductive electrodes (on the left) and a sinusoidal conductive yarn for heating element (on the right) – by CTT Group.

3-dimensional patterns allow the stacking of the yarn in the z-axis in order to create net-shape structure; meaning that the product will not require additional production steps like cutting or trimming to achieve the desired dimensions.

Aside from cost and times savings, from a production point of view, TFP is also a way to create a more resilient fabric structure. By stitching each yarn on another, the risk of delamination and the shear resistance is greatly improved when compared to 2D fabrics stacked together to reach the same thickness.

Figure 3 : Carbon Fiber placement on a non-woven by CTT Group

CTT Group’s new embroidery system has all of the newest features to create a complex fabric structure. Completely carbon-proof it includes a two-yarns feeding system in order to simultaneously process two different materials; carbon and glass for instance for composite applications.

The TFP head is also equipped with a sequin device. We use it to process a controlled placement of electronic components when working with conductive yarns for smart textile applications.

As we learn to master our latest addition to our prototyping equipment, we encourage you to reach out to us with your project ideas and help us test the limits of this new technology!

You may address your questions to: info@gcttg.com