Spinning line is composed of a carding machine, a miniature drawframe & mini ring spinning lab

Production of yarn prototypes by ring spinning

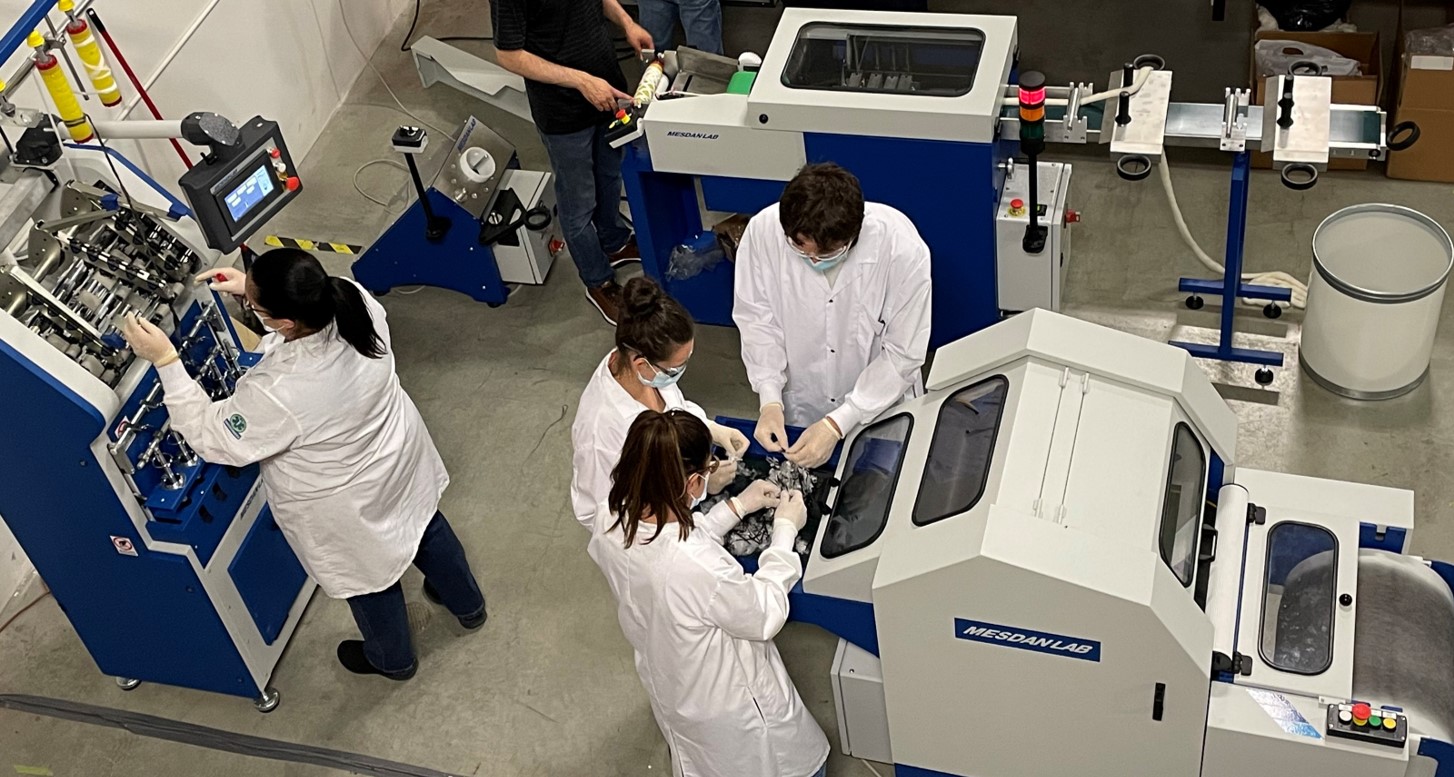

First yarn prototypes on the CTT laboratory spinning line

This state-of-the-art equipment is versatile and gives us the opportunity to work for different applications :

- Evaluation of the capacity to use recycled fibers from shredding processes

- Recycling post production or post consumer textiles is one of the tools for waste management and contribute to the Sustainable Development Goals (https://www.un.org/sustainabledevelopment/) . This equipment will give the opportunity to industrial partners to evaluate the feasibility of yarn using these types of recycled fibers.

- Evaluation of yarn spinning with natural fibers

- With a growing demand for natural fibers and project to explore potentials with such fibers, there is a need to evaluate the possibility of yarn processing. This equipment will help manufacturers for proof of concepts, optimisation of yarn, and much more.

- Evaluation of fiber blends properties

- One step ahead : testing a new blend of fiber to reduce raw materials cost, carbon footprint, simplify your supply chain.

The equipment is made of 3 modules :

- Laboratory carding machine

- Miniature drawframe

- Mini ring spinning lab

Additional prototypes such as woven and knitted materials is also available to complete industry project. Our prototyping capacities.

Once the yarn is produced (or a fabric), a performance testing is available at CTT.

Quick view of the training session by Mesdan, at CTT : Mini ligne de filature pour prototypage de fils

This equipment is operating since june 2022

Data at a glance :

Minimum fiber need : 50 grams

Fiber type : short staple fibers 20 to 102mm (0.75” to 4”)

Average production (Card) 4kg/h

Spinning machine : 6 spindles

Yarn size : Ne 8 up to Ne 80 ( 7 to 74 Tex) [ 66 denier to 664 deniers ]

More information : info@gcttg.com