SAGEOS Experts will be present during the 12th International Conference on Geosynthetics, in ROMA, 17-21 September 2023.

This conference is important to share knowledge and expertise for geosynthetics experts and manufacturers.

SAGEOS is presenting some of the projects that are conducted in our Research Laboratories to support the development of materials, characterization of products and method developments for industrial partners.

The following papers are presented during this 2023 edition :

In the TS S24: Design Approaches and other Applications

“Water drainage and gas collection with geocomposites – Hydraulic software development”

Stephan Fourmont (1), Justine Decaens (2), David Beaumier2, Mathilde Riot (3)

- Afitex-Texel, Canada;

- CTT Group-SAGEOS, Canada;

- Afitexinov, France

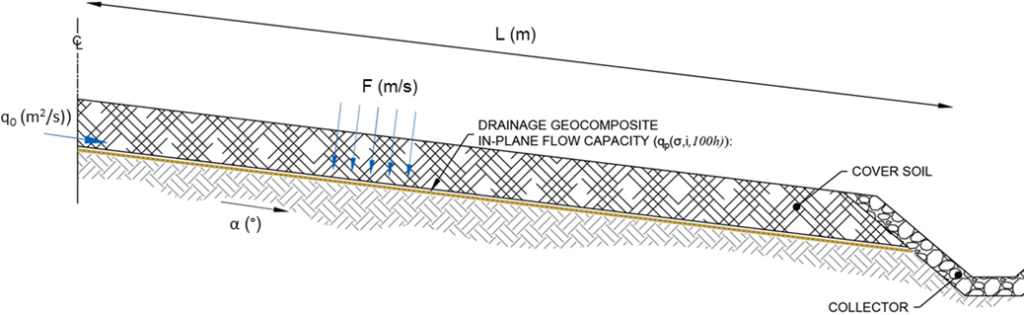

Lymphea – Drainage geocomposites (Stephan Fourmont, Justine Decaens, David Beaumier, Mathilde Riot)

Lymphea – Drainage geocomposites (Stephan Fourmont, Justine Decaens, David Beaumier, Mathilde Riot)

Geosynthetic materials and, more specifically, drainage geocomposites are now widely used for water drainage and gas collection in applications as varied as water drainage and gas collection on final landfill covers, leachate collection in landfill cells, sub-slab depressurization system under buildings, groundwater drainage under embankments, etc.

The design methods used are based on the in-plane flow capacity of the geocomposites, which is determined by laboratory tests on a 250-300 mm long product sample. The fluid is injected into the thickness of the product and this drainage capacity is interpolated for actual lengths of several tens of meters.

This paper presents the development of hydraulic design software for multi-linear drainage geocomposites, based on laboratory characterizations of the geocomposite and validation with full-scale tests. The software gives a 3D model of the hydraulic curves in the geocomposite depending on the application for which the geocomposite is used, and the fluid to be drained (water, landfill gas, methane, air, etc.).

Design examples using the software will also be given.

TS S28: Landfill and Remediation of Contaminated Sites

“The compatibility and equivalency of natural and geosynthetic materials for the design of landfill barriers”

Hajer Bannour

ISSAT SOUSSE, Tunisia

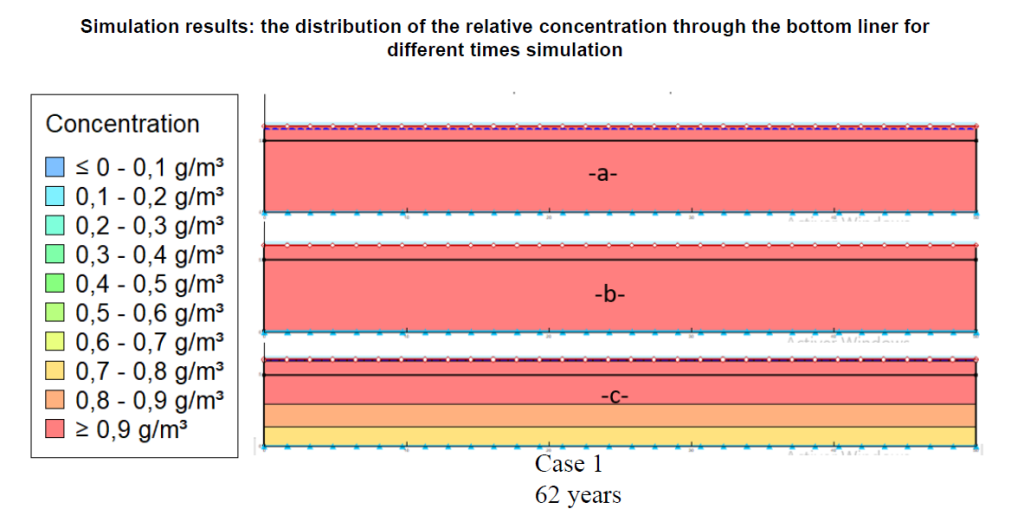

Distribution of the relative concentration through the bottom liner for different times simulation (Hajer Bannour)

Distribution of the relative concentration through the bottom liner for different times simulation (Hajer Bannour)

Waste disposal facilities (landfills) need to be designed with two distinct and complementary barriers, active and passive. In order to prevent contamination of subsoils and groundwater by the leachate provided by wastes, passive barriers need to be installed with very strict regulations. Nonetheless, with the luck of natural sites meeting regulations and considering economic and technical concerns, designers used to perform equivalency on a landfill geographical site by considering the potential environmental impact of wastes on water resources and aquifers.

In this equivalency study, analytical and numerical analyses have been performed on relative concentration evolution of contaminants through the geosynthetic reinforced barrier and soil liner in comparison with conventional passive barriers in the same contamination configuration. Numerical modeling has been used to reproduce leakage and contaminant transfers into the entire barrier to the aquifer by SEEP/W and Ctran from Geostudio (2012).

In this study, we found that the reinforcement of the passive barrier with a Geosynthetic clay liner (GCL) and the reduction of the low permeable layer thickness increased the performance of the whole barrier by limiting the evolution of the contaminant migration into the groundwater and subsoil as compared to the regulatory one. In conclusion, equivalency is possible for passive barriers; however it is important to pay attention to contaminant transfers and the amount they involve with time.

TS S06: Geosynthetics Properties and Testing

“Performance of various techniques used to increase the interface shear-trength properties of polyethylene geomembranes”

Eric Blond (1), David Beaumier (2), Catrin Tarnowski (3)

- Eric Blond Consultant, Canada;

- CTT Group-SAGEOS, Canada;

- Solmax, Germany

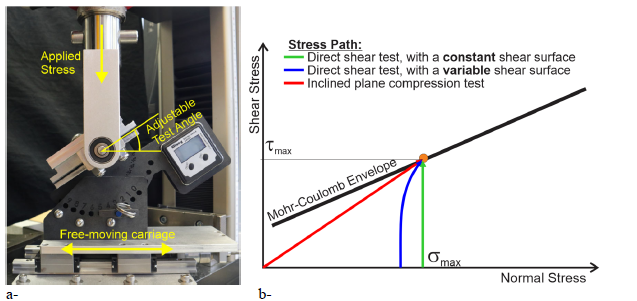

Inclined plane compression test setup. (Eric Blond, David Beaumier, Catrin Tarnowski)

Geomembranes can be produced with or without surface texture. This choice is generally driven by design requirements, in particular the slope stability, but also the safety of users and wildlife. Overall, a bit less than half of textured geomembranes worldwide are produced by coextrusion, a bit more than a third are embossed, and a bit less than a fifth are sprayed with polyethylene filaments.

For coextruded textures, Blond and Elie (2006) have shown that there is a correlation between the height of the asperity, measured by ASTM D7466, and the shear-strength properties of the interface between the geomembrane and an adjacent material. Adesokan and Blond (2018) have shown that the density of asperity may also further influence the interface shear-strength properties. However, there is little information available on the performance of the two other texturing techniques frequently used for geomembranes, i.e., embossing the surface, or spraying it with polyethylene particles. Finally, there is a consensus on the limited performance of ASTM D7466 to adequately predict the performance of geomembranes with an embossed or a spray-on texture.

In this document, the various techniques used to create a surface texture on a polyethylene geomembrane are described. The results of an experimental program aiming at measuring their shear-strength properties against a geotextile and a soil is presented. Various methods used to characterize the different types of texture are exposed and criticized.

Finally, a universal strategy to qualify the performance of textured geomembranes is proposed, which can be used for quality control as well as to predict the long-term performance of the texture.

Please address your questions or comments at info@gcttg.com